SERVICE SUPPORT

BEIYANG PUMP INDUSTRY

-

-

CHEMICAL INDUSTRY

-

ENVIRONMENTAL PROTECTION WATER TREATMENT

-

FOOD AND BEVERAGE

-

EQUIPMENT MATCHING

-

ELECTRONICS INDUSTRY

-

NEW ENERGY

-

CERAMIC INDUSTRY

-

COATING INDUSTRY

-

AUTOMOBILE PRODUCTION

-

COAL MINE

-

PHARMACY

-

MARITIME SHIP

-

-

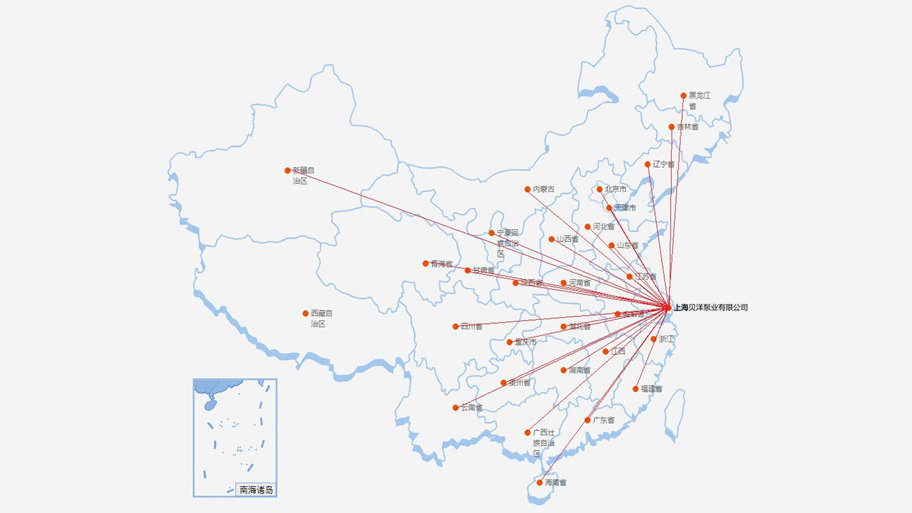

BASED IN SHANGHAI, LOOK AT THE WHOLE COUNTRY AND GO TO THE WORLD

BASED IN SHANGHAI, LOOK AT THE WHOLE COUNTRY AND GO TO THE WORLD -

In the process of daily use of diaphragm pumps, it is inevitable that there will be certain failures. If you really want to ensure that the equipment has a good application effect and avoid failures, you also need to know how to repair some failures. Shanghai Beiyang Pump Industry has summarized some common faults. If similar problems occur, simple treatment can also restore the application of the equipment.

1. Common failures of diaphragm pumps Failures can be divided into a variety of possible causes. Know the correct pre-maintenance measures.

1. Air valve: plastic or metal valve housing is fixed on the pump center body by four screws;

2. Piston: The aluminum cylinder is enclosed in the air valve to control the air flow;

3. Cavitation: Due to the decrease or lack of fluid supplied to the pump inlet, the pump discharge volume is lower than the rated volume. In fact, the liquid chamber is not filled with fluid before discharge;

4. Static discharge head: the vertical distance (in meters) from the center line of the pump to the free delivery point;

5. Inlet pressure: the inlet is measured in Bar, including the specific gravity and flow rate of the fluid;

6. Specific gravity: The ratio of fluid weight to water weight at 4 degrees. The specific gravity of 4 degrees water is 1.0, and the static suction lift is the vertical distance from the liquid surface to the center line of the pump. The pump should be above the liquid surface;

7. Vapor pressure: The vapor pressure of all liquids on its free surface. In any pump operating system, the operating pressure cannot be lower than the vapor pressure, and the formed vapor will be partially or completely cut off into the pump fluid;

8. Viscosity: Due to the internal friction of the fluid, the nature of viscosity makes the fluid flow resistance;

9. Water hammer effect: The higher inlet forms a static pressure head which acts on the pump to generate internal pressure.

2. Troubleshooting of diaphragm pump

Malfunction: The diaphragm pump does not move or operates very slowly;

Exclusion: 1. Check whether the filter screen or air filter device at the air inlet end has impurities;

2. Check whether the air valve is stuck, and clean the air valve with cleaning fluid;

3. Check whether the air valve is worn and replace with new parts if necessary;

4. Check the condition of the sealing parts of the center body. If it is severely worn, the sealing effect cannot be achieved, and the air will be discharged from the air outlet end. Because of its special structure;

5. Check whether the movement of the piston in the air valve is normal;

6. Check the type of lubricant. If the added lubricating oil is higher than the recommended oil viscosity, the piston may be stuck or not functioning properly. It is recommended to use thin and anti-freezing lubricating oil;

7. Check that the pump is moving, but the flow is small or there is no liquid flowing out at all;

8. Check the cavitation of the pump, reduce the speed of the pump to let the liquid enter the liquid chamber;

9. Check whether the valve ball is stuck. If the operating fluid is not compatible with the elastomer of the pump, the elastomer will swell. Please replace the elastomer with an appropriate material;

10. Check whether the connection of the pump inlet is completely locked and not leaking, especially the clamp near the valve ball at the inlet end needs to be locked.

Trouble: The air valve of the pump is freezing:

Remedy: Check whether the water content of the compressed air is too high, and install air drying equipment.

Trouble: Bubbles are generated at the outlet of the pump

Remedy: Check whether the diaphragm is broken, check whether the clamp is locked, especially the inlet pipe clamp.

Trouble: The product flows out from the air discharge port

Remedy: Check whether the diaphragm is broken, check whether the diaphragm and the inner and outer splints are clamped on the shaft, and the valve rattles. -